The most suitable screw geometry is selected by means of a computer assisted design system in accordance with the chemical/ physical characteristics of the solid-state material and with the rheological data of the melt. A 3-D CAD system with finished elements analysis module is used to evaluate the mechanical and thermal solicitations. The screws geometry allows the machine to process the material in a soft way, by keeping a proper energetic supply of motor, material and heating system; therefore a better quality of the extruded product is achieved with a high output rate. The project parameters of the screws, such as the compression ratio and the chambers filling, enables us to obtain proper cutting actions, with remarkable advantages for a longer life of the screws and barrel. On the barrel, the temperature control system is made through the following manufacturing features: • barrel heating through a low-thermal-inertia system for an accurate control of the temperature; • cooling system by high capacity blowers and highly efficient thermal dissipaters for thermal exchange or, in the bigger models, by oil forced circulation in a spiral circuit integrated in the barrel; • L-distribution of the heating elements in order to keep the temperature constant and avoid any possible thermal deformation of the barrel; • set temperature control through P.I.D. algorithms. Screws thermoregulation is made as follows: • oil power unit with high-output-circulation for a oil flow with high turbulence and efficient thermal exchange; • ACTherm closed-circuit system.

The most suitable screw geometry is selected by means of a computer assisted planning system in accordance with the chemical/ physical characteristics of the solid-state material and with the rheological data of the melt. A 3D CAD system with finished elements analysis module is used to evaluate the mechanical and thermal solicitations. For a further improvement of the quality of the melt characteristics and at the same time to satisfy some particular working requirements, the screw can be featured by mixing zones with dispersing and distributing elements with characteristics suitable for the different applications. The wide range of geometries allows optimizing the performances. In fact there are available screws: • dedicated to particular materials to maximize the performances; • multi use to reconcile versatility and performance. Screw and barrel can be in execution for single or double vent system through water-ring pumps and, for particular requirements like high vacuum level, through dry-pump groups. On the barrel, the temperature control system is made through the following manufacturing features: • positioning and dimensioning of the temperature control zones according to the different screw geometries; • cooling system by high capacity blowers and highly efficient thermal dissipators for thermal exchange; • L – distribution of the heating elements in order to keep the temperature constant and avoid any possible thermal deformation of the barrel; • set temperature control through P.I.D. algorithms.

The most suitable screw geometry is selected by means of a computer assisted design system in accordance with the chemical/ physical characteristics of the solid-state material and with the rheological data of the melt. A 3-D CAD system with finished elements analysis module is used to evaluate the mechanical and thermal solicitations. The project parameters of the screws, such as the compression ratio and the chambers filling, enables us to obtain proper cutting actions, with remarkable advantages for a longer life of the screws and barrel. The vent system allows an efficient evacuation of the volatile elements during the fusion process. The vacuum unit, easily accessible, is protected by a filtration group equipped with bypass which avoids any interruptions during the maintenance operations. Thank to our long experience, JINHAI has also developed specific screw geometries for different applications, obtaining a very good thermic stability at low working temperatures and high performances also with an absorbed power extremely reduced. In this case also, thanks to the different technical solutions, the technology developed by JINHAI during its long experience, counter-tend compared to the easy market choices dedicated to the production in series, can fit the most exigent needs of the customers.

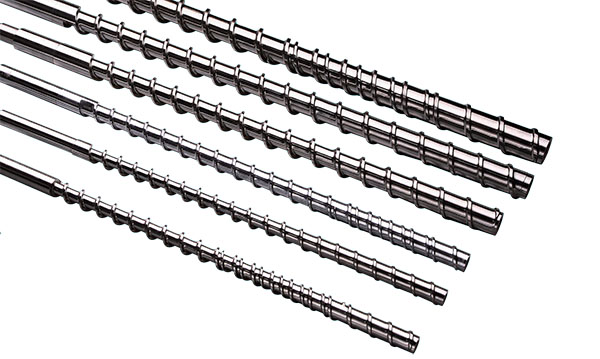

Replacement screws and barrels from JINHAI increase the quality and the output of any extruder. JINHAI has outstanding experience in the design and development of plasticizing units, which are applied to our own range of machines as well as to replacement units (cylindrical or conical) for twin-screw extruders of all types on the market.

At an early stage JINHAI focused on it‘s development activities on corrosion-proof plasticizing designs of barrels, liners and screws, enabling solving problems optimal and guaranteeing a long service life. The manufacturing of more than 20.000 screws and barrels – in a wide variety of sizes and versions – has led to an extensive know-how in development and manufacturing. Thus manufacturing of units designed to optimally meet the processing needs of the customer and providing the highest possible reliability and quality.

d or coated, cylindrical or conical, with variable pitch or core progression, with shear, mixing or kneading zones – whatever the process technologists engineers require, JINHAI will manufacture.

All parts are manufactured to JINHAI original drawings, customer drawings or individual design for all extruder models from JINHAI and other leading manufacturers worldwide.

Twin-screw barrels are predominantly manufactured using CNC machines. Stipulated by the DIN ISO 9001:2015 quality management system, measurement and testing (and logging of such) activities start with blanks and extend to the final products. Special machines and manufacturing devices have been developed and are deployed by Extruder to produce parallel and conical twin bore holes by forms of deep hole spindling, boring and honing.

The plant is equipped with state-of-the-art equipment for the production of nitrided twin-screw barrels. All components are manufactured in accordance with our high standards of quality, for the most part on computerized numerically controlled machines.

• many years of experience in developing and manufacturing guarantees precise execution

• a proven processing method to apply a molybdenum layer on the screw surface extends the lifetime of the plasticizing unit

• the economical energy consumption of our units sets a trend typical for industrial development

• a balanced screw geometry to suit a wide range of formulations ensures good homogenity, even at high screw speed

• the screw flight depth design is tailored to meet the viscosity and flow characteristics of PVC extends the lifetime of barrels and screws

• special geometries for processing of fibers and food are available

• Screws for extruders and injection molding machines

• Parallel and conical twin screws and barrels

• Single screws and barrels

• Bimetal barrels for single and twin screws

• Casings and screw shafts for compounding extruders

• Rebuilding of screws, barrels and casing

• Precision parts for the machinery industry

• Refinishing: deep boring, honing, turning, abrading, welding of long distances, parallel & conical

Single- and Twin-Screws:

In many extrusion applications, nitrided twin screws are used. In demanding

applications, coating of the screws is desirable. For the coating, layers of

molybdenum have shown excellent sliding and low friction running conditions.

For other applications wear resistant layers with Ni/Co-basic alloys as well

as specially developed and modiefied tungsten carbide alloys are necessary.

JINHAI’s plasma-welding and plasma-spraying technologies make it possible to arm the screws with surface protections against wear.

Single- and Twin-Screw Barrels

For the deep boring and honing, especially for conical bore holes,

JINHAI has developed special machinery. JINHAI’s manufacturing

techniques, when used with suitable raw materials and

applied with the experience of our qualified technicians, lead to

precision parts with accurate dimensions.

Deep nitriding of barrels improve the wear behavior. For higher

demands the barrels are offered with changeable bimetal liners.

Bimetal barrel:

JINHAI developed special alloys to insert bimetal-liners in all kind of twin screw barrels. This allows a higher resistance for abrasion and chemical corrosion.

All bimetal-alloys are optimized to JINHAI screwcoating systems for our twin

screws to guarantee an optimum on lifetimeand process results.

The JINHAI system can be offered for all plastification units on the free market and sets new standards in price and efficiency.