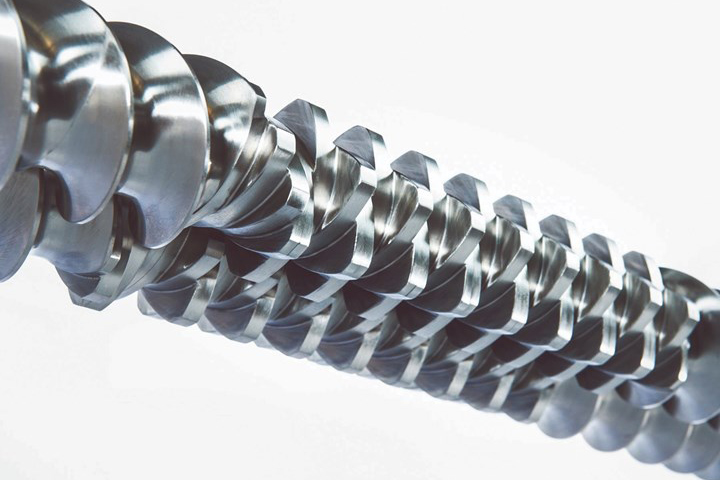

The corotating, intermeshing twin-screw extruder (TSE) is the compounding industry’s most prevalent device for continuous mixing of polymers with additives and fillers (Fig. 1) . Exotic formulations that utilize atypical active ingredients are also processed on this type of machine. Materials exposed to high shear and temperatures will degrade. Almost every product benefits by strategically managing how shear (and energy) is imparted to the materials being processed and is measured by the resulting melt temperature.

Various factors must be considered to manage and control the melt temperature. In this article, emphasis will be given to OD/ID ratio, the melting zone in the screws, and front-end design.